Introduction of pallet tilter

LT series lift and tilt pallet jack are designed to lift the pallet and tilt it to the ergonomic angle. LT10M manual pallet tilter & LT10E electric pallet tilter are worked to allow the users to ergonomically reach loads easily without having to bend down or over-stretch. The Electric tilt pallet jack has forced steering on one wheel to make manoeuvring easy. Lift /lower functions are controlled by a switch on the control lever. Tilt/return functions are controlled by a remote control, which is fitted with a long wire, and can make the operator and the tilter with load keep a certain distance, more safer. Lift /lower function and Tilt/return functions can be operated independently of each other or simultaneously. When Tilt/return functions are to be used, the tilter must be on a firm surface, and the universal wheel shall be braked. When Tilt/return functions are to be used to stack materials, the handle can be turned to the side to make access to the stack table easier.

As a pallet tilting equipment, this pallet jack tilter can be used as a pallet truck and also a tilting pallet truck, this can not only improve your work efficiency, but also save costs.

Die handvatsel kan gedraai en toegesluit word in 'n posisie weg van die werkarea. Dit is van toepassing op sit- en staanposisies. Die vurke van die palet-kantelingskanaal kan tot 90 grade gekantel word. Albei word standaard voorsien met parkeerrem en voetbeskermers.

Voldoen aan EN1757-1 en EN1175

Details of pallet tilter

LT0M manual pallet tilter LT10E electric pallet tilter

We have this item in stock in France/US, if you are located in Europe or US, we can arrange delivery to you ASAP! This way will save your time and shipping cost.

Specifications of pallet tilter

| i-lift No. | 1520902 | 1520903 | |

| model | LT10M | LT10E | |

| tipe | handleiding | Electric | |

| kapasiteit | kg (£). | 1000(2200) | |

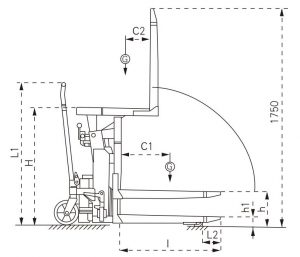

| Hefhoogte, vertikaal | h mm (in.) | 285(11.2) | |

| Min.vloerhoogte | h1 mm (in.) | 85(3.3) | |

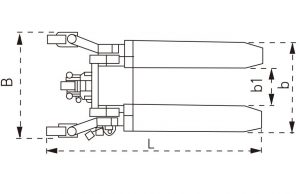

| Vurklengte | I mm (in.) | 800(31.5) | |

| Hanteer hoogte | L1 mm (in.) | 1138(44.8) | |

| Algehele vurkwydte | b mm (in.) | 560(22) | |

| Breedte tussen vurke | b1 mm (in.) | 234(9.2) | |

| Lengte van die vurkpunt vanaf die rol | L2 mm (in.) | 135(5.3) | |

| Algehele breedte | B mm (in.) | 638(25.1) | |

| Algehele lengte | L mm (in.) | 1325(52.2) | 1410(55.5) |

| Algehele hoogte, verhoog | H mm (in.) | 950(37.4) | |

| Totale hoogte, verlaag | H mm (in.) | 750(29.5) | |

| Laai sentrum Min./Max. | C1 mm (in.) | 200/400(8/16) | |

| Laai sentrum Min./Max. | C2 mm (in.) | 200/420(8/16.5) | |

| Krageenheid | KW / V | -- | 0.8/12 |

| Netto gewig | kg (£). | 178(391.6) | 185(407) |

Veiligheidsreels

1. Driving the pallet tilter on the slope

1) The pallet tilter shall be unloaded or a small load.

2) Die las moet in die laagste posisie wees.

3) The gradient shall be no more than 2° when dragging the pallet tilter.

4) Die operateur moet op die boonste posisie wees, of dit nou opgegradeer of afgradeer word.

2. Avoid offset loads

Die las moet eweredig op vurke of palette versprei word, met 'n afstand van 400 mm tussen die swaartepunt en die vurke voor, die maksimum hoogte van die swaartepunt is 420 mm, die minimum is 200 mm, die afstand buite hierdie bestek verminder die vlak van veiligheid en verhoog die risiko.

Goedere op palette of vurke moet behoorlik vasgemaak wees, vermy dat die vrag gebalanseerd is, sodat dit nie kan afval tydens vervoer, wanneer die vragmotor opgelig word nie, of wanneer die vragmotor 'n rukkie oplig.

3. Driving loaded

The tilting pallet jack is designed for use on even and level floor. During transport the forks shall be raised as little as possible. Transport with raised forks should be made over the shortest possible distances and at low speed. Do not transport when tilting goods on the pallet tilter, this is not safe.

waarskuwing: Moet nooit hande of voete op die bewegende dele plaas nie, met die risiko van beserings.